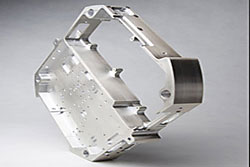

Military grade products and state of the art technology

MACHINING VIDEO

APC Inc. implements state of the art CNC equipment capable of turning or milling micro parts to large scale parts using various materials from common metals and plastics to exotic alloys holding tolerances of +/- .0001.

APC Inc. implements state of the art CNC equipment capable of turning or milling micro parts to large scale parts using various materials from common metals and plastics to exotic alloys holding tolerances of +/- .0001.

SERVICES OVERVIEW

As a full service Machine Shop APC Inc. will draw from the customers supplied drawing to take all the necessary steps to deliver exactly what the customer ordered. Starting with contract review, planning, programming, first article inspection, production, out-process, final inspection, all the way to on time delivery.

As a full service Machine Shop APC Inc. will draw from the customers supplied drawing to take all the necessary steps to deliver exactly what the customer ordered. Starting with contract review, planning, programming, first article inspection, production, out-process, final inspection, all the way to on time delivery.